The mining sector, defined by its complexity and high stakes, sits at the epicentre of technological transformation. Success is measured not only by tonnes extracted but by the ability to integrate productivity, safety, sustainability, and operational excellence. Digitalisation and AI are driving a significant transformation in the mining industry, making it safer and more efficient, as seen in South Africa’s recent progress. These innovations contributed to a remarkable 24% reduction in mining fatalities in South Africa, dropping from 55 in 2023 to a historic low of 42 in 2024.

Probe IMT, a leader in providing integrated mining solutions, is driving this transformation through strategic partnerships and a keen focus on emerging technologies. By implementing advanced solutions in Collision Avoidance, real-time monitoring, private 5G, advanced LED lighting and vehicle safety, Probe IMT harnesses next-generation technologies to actively redefine the mining landscape.

“Visionary mining leaders have realised it’s time to transform how operations are conducted, rather than simply searching for incremental improvements,” says Gert Roselt, CEO of Probe IMT. “Accurate, real-time data forms the backbone of this transformative approach, supporting everything from rapid decision-making to predictive maintenance and regulatory compliance as we move towards a safer, Zero Harm future.”

Advanced Collision Avoidance

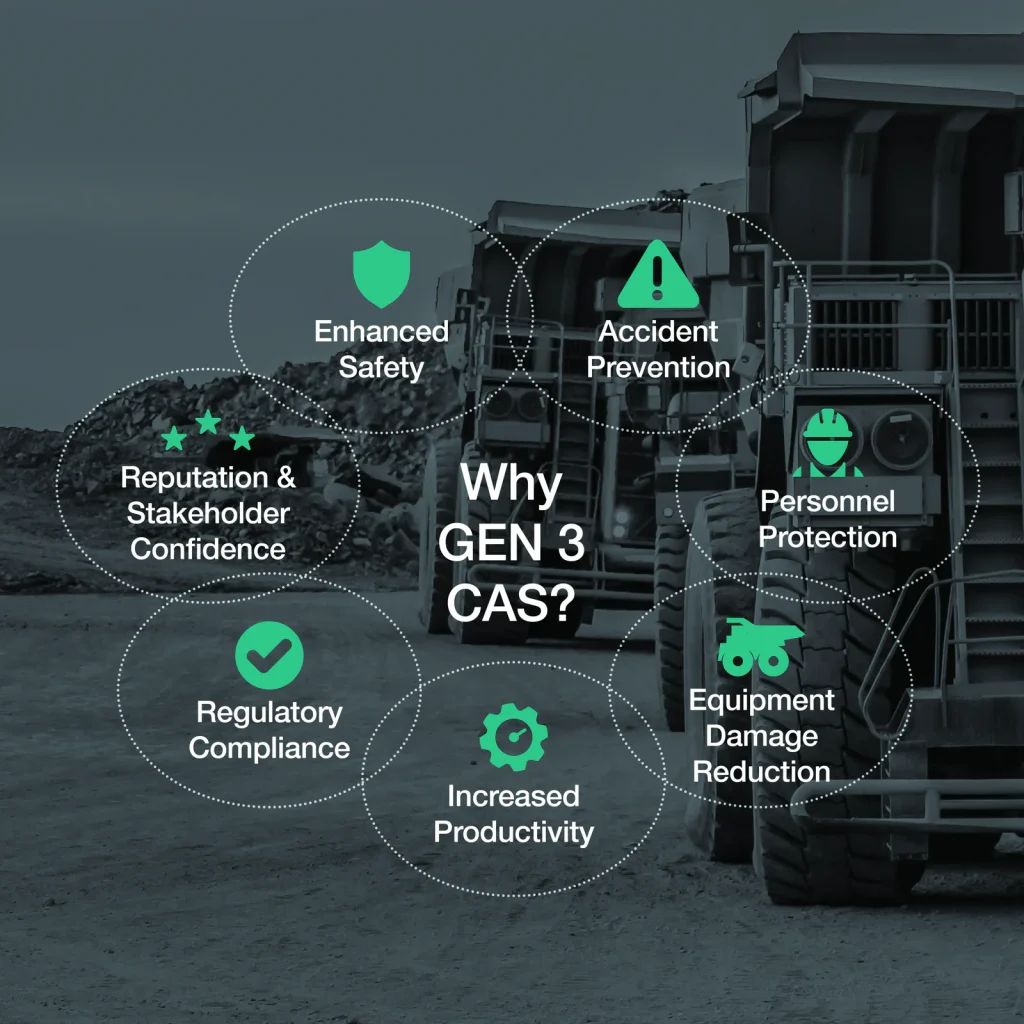

Mining vehicles operate in hazardous environments, making collision prevention a top priority. Probe IMT’s deployment of the Wabtec Collision Avoidance System (CAS) Generation 3 is a leap forward in mine fleet safety. Developed after years of collaboration, field testing, and drawing from client insights, CAS Gen 3 is setting the standard for EMESRT Level 9 compliance, which has become mandatory in both surface and underground mining in South Africa.

Key features include:

- Ultra-high accuracy sensing to minimise false alarms and deliver up to 50x better alarm performance compared to competitor systems.

- 360-degree situational awareness via advanced sensors and intelligent vision systems that reduce the risk of vehicle-to-vehicle, vehicle-to-personnel, and vehicle-to-infrastructure interactions.

- Real-time system health monitoring, enabling remote diagnostics, troubleshooting, and system configuration for uninterrupted operations.

- User-centred, intuitive interfaces with adaptability to site-specific requirements, ensuring seamless fleet-wide deployment.

- Advanced analytics that identify hazardous site conditions and non-compliant operator behaviours, facilitating immediate remediation.

A powerful case study highlights how, in an Australian coal mine, CAS Gen 3 analytics identified unexpected alerts caused by shrinking haul road widths due to wet weather. This actionable data enabled operators to address the risk before it resulted in an accident. With over 15 years of operations and no fatalities, Wabtec’s commitment to safety and reliability is both proven and future-ready.

Real-time environmental monitoring and 5G

Operational excellence and workforce safety depend on real-time, actionable information. Probe IMT’s collaboration with M3SH Technology leverages state-of-the-art sensor platforms and a secure, dedicated private 5G wireless network, transforming environmental monitoring and asset protection in mining operations.

M3SH real-time monitoring integrates solutions such as:

- Environmental hazard detection (P50, S50, D52, P511, NM20, DPM50) for real-time alerts on air quality, smoke, fire, airborne particulates, ventilation, noise, and diesel particulates.

- Automated response mechanisms, such as activating ventilation or dust suppression when thresholds are breached, supporting compliance with Mine Health and Safety Act (MHSA) and reducing workforce exposure.

- Private 5G infrastructure, delivering ultra-fast, low-latency data connectivity deep underground, ensuring that data from advanced sensors is communicated instantly from last mile to the surface for immediate analysis.

- Motor protection and predictive maintenance with the M20-series, M550 relay, and PSU3000 power supply, safeguarding critical machinery and limiting unplanned downtime.

At the Impala Bafokeng mine, Probe IMT and M3SH’s real-time sensor technology, supported by private 5G, form a digital backbone recognised by authorities as essential for effective health hazard monitoring and compliance. Probe IMT delivers a comprehensive solution, including staff training and ongoing maintenance support, furthering the sustainability of digital mine initiatives.

Safe illumination with advanced LED Lighting

Visibility and energy management are vital elements in the drive towards both safer and more profitable mining operations. Probe IMT’s partnership with Vision X has elevated industrial lighting solutions, moving away from outdated sources toward advanced, energy-efficient LED platforms tailored for mining environments.

Advantages of Vision X LED lighting include:

- Customised lighting designs for specific equipment and site conditions using 3D modelling and simulation, ensuring optimal placement, reduced glare, and maximised safety.

- Up to 80% brighter output than conventional lighting, reducing fatigue, boosting worker alertness, and consequently, improving productivity.

- Significant cost and energy savings, with one case study demonstrating a five-year saving of over $99,000 across an OEM plant due to LED retrofits and extended service life.

- Environmental benefits, including reduced power consumption, lower emissions, and minimised waste

- Advanced features like selective yellow anti-glare lenses improve visibility in foggy or low-contrast conditions

With comprehensive fit-out guides and tailored configurations for every application—from haul trucks to underground drifts—Vision X lights installed by Probe IMT help unlock new levels of efficiency, safety, and sustainability in mining.

Custom harness solutions from Harntech

Reliable electrical infrastructure is essential to the operation and safety of modern mining equipment. Probe IMT’s partnership with Harntech delivers OEM-grade harnesses designed for the harshest conditions, tailored precisely to client needs.

Harntech harness innovations provide:

- Rapid turnaround on custom-engineered wiring harnesses, avoiding long lead times and ensuring seamless integration.

- State-of-the-art manufacturing standards (ISO 9001, IPC/WHMA-A-620)

- Durability and reliability via heavy-duty, moisture- and dust-resistant connectors, and high-temperature, oil- and diesel-resistant wires.

- Comprehensive support, including site assessments, root-cause investigations, drawing and design services using advanced CAD, and supply of ready-to-fit kits.

A case at an iron ore mine in the Northern Cape shows this value. Downtime caused by lighting circuit failures on Caterpillar haul trucks was resolved through Harntech’s custom-designed, plug-and-play electrical kits and upgraded harnesses, resulting in a substantial increase in uptime and fleet-wide adoption of the solution.

Vehicle Safety Solutions

Probe IMT integrates Brigade’s advanced safety systems, such as 360-degree camera systems, radar obstacle detection, and reversing alarms, to eliminate blind spots and prevent collisions in mining environments.

Probe IMT further leverages Optix’s AI-powered fleet management tools, including DriveCam and Mobileye, to monitor driver behavior, prevent accidents, and provide real-time performance insights. These technologies ensure proactive safety measures and operational efficiency, tailored to the rigorous demands of mining operations.

Integration and ongoing support

What stands out about Probe IMT’s approach is the emphasis on total solution delivery. From technical design and professional installation to ongoing site support, predictive maintenance, and skills training, Probe IMT partners closely with clients to ensure long-term value creation. Their expert field services division is available around the clock, deploying digital diagnostic tools and predictive maintenance platforms to limit unplanned downtime and maximise asset availability.

The rapid pace of technological evolution means that what is best practice today quickly becomes tomorrow’s baseline, says Roselt. “Our focus on integrating global best-of-breed technologies, deep expertise, and close client collaboration delivers measurable improvements in safety, productivity, and cost efficiency. This approach positions our clients—not only to remain compliant and competitive—but to set new benchmarks in industry performance.”

For mining operations looking to harness the full value of modern technology, Probe IMT stands ready as a partner for a safer, smarter, and more productive future.

For more information, visit probeimt.co.za or contact the Probe IMT team at +27 (0) 10 634 5605 / +27 (0) 86 045 3789.

Branches across Sub-Saharan Africa and value-added partners across Africa.